how to make a program in Honeywell SoftMaster

Published on May05, 2023 | Category: SoftMasterHoneywell SoftMaster is PLC programming ang configuration software developed by Honeywell. Honeywell SoftMaster used for ML(master logic) series plc. Honeywell SoftMaster supports all basic programming language of plc like Ladder Diagram (LD), Sequential Function Chart (SFC), Structured Text (ST), and Instruction List (IL). and also support all IEC61131-3. this software comes with all plc standard instruction like scaling, pid, timer, counter, arithmetic, comparison, communication, data shift, analog instruction etc. and support string function. Honeywell SoftMaster support all basic communication protocol. Honeywell SoftMaster has simulator features which is help full to test, analyses and debug program of plc without download to original plc.

supported PLC in honeywell SoftMaster

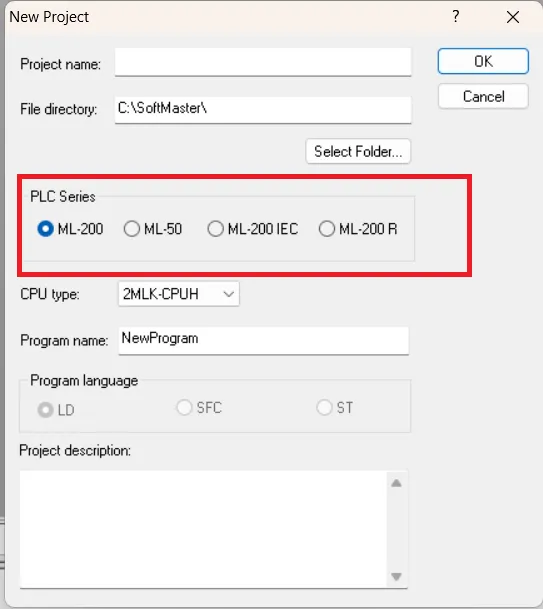

SoftMaster support only ML series plc. different series of ML series plc have diffrent features and memory sizes of plc's. SoftMaster help to configuration of I/O module of plc , communication setup for plc, modbus and mapping etc. in ML series have different CPU type you select at beginning of new project or latter. following are ML series PLC :

- ML 200

- ML 200 IEC

- ML 200 R

- ML 50

create a new project in Honeywell SoftMaster

open Honeywell softMaster and go to project menu and create a new project, a new project dialog will open on your screen enter the name of , set path for project select type of plc , select cpu type from drop down menu each ML series have different cpu type, enter program name and then select programming language of your plc In Program language, select the LD or SFC or ST as per requirement. Press ok to create a new project. if you want you also enter a project description but it's optional.

Configure basic parameters of PLC in honeywell softMaster

in project window parameter than open basic parameter, basic parameter is a basic setting of plc.

a basic parameter setting dialog will open. basic parameter dialog have following tab which are use for configuration.

- Basic operation setup Tab this tab use for define parameter like scan time, Restart Method, D.CLR Overall Reset Switch Setup etc.

- Retain area setup Tabin this tab we configure retained memory area

- Error operation setup Tabthis tabs used To specify when an error occurs in the PLC.

- MODBUS setup Tabin this tab used for specify Modbus parameter.

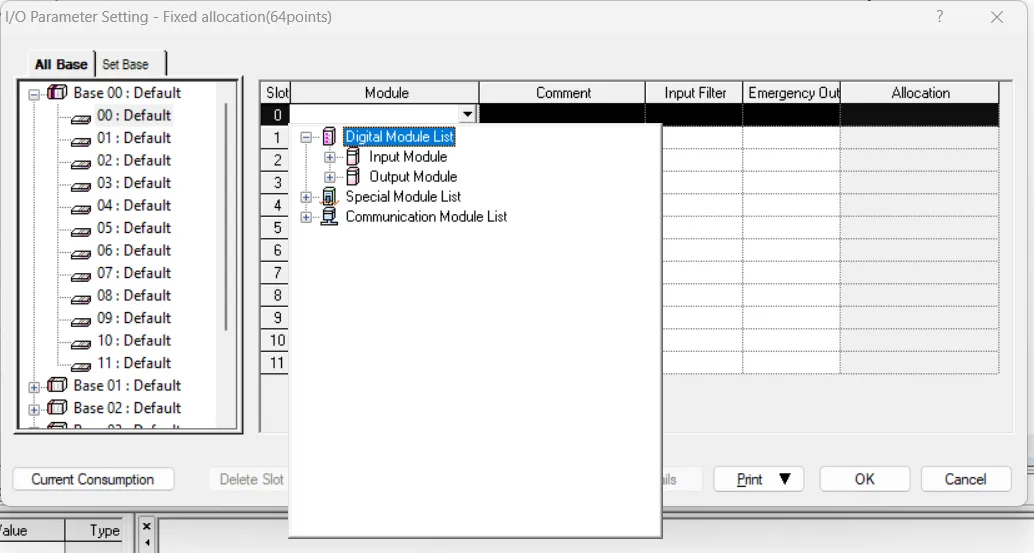

Configure I/O Parameter of PLC

in I/o parameter specify slot number for I/O module, insert a new analog, digital, RTD, communication module in a slot. to open I/O parameter setting in project window under parameter double click on I/O parameter.

Decalare variable for plc

in honeywell softMaster all supported plc have two types of variables first is local variable which used inside the program and global variable which used all program. declare variable type as per your requirement and enter name, address etc to declare a variable. You can use these variable in a plc program.

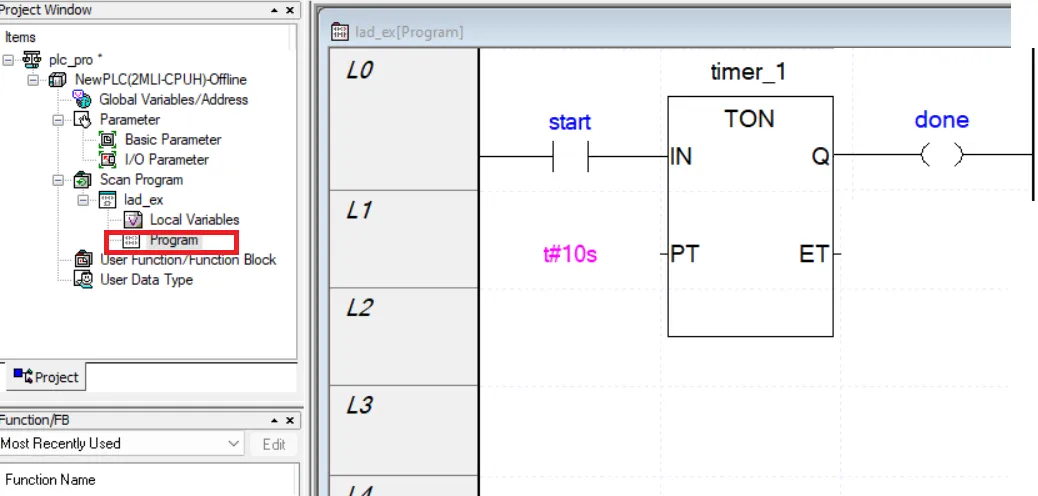

create a user program in honeywell SoftMaster

in honeywell softmaster you can make two type of program which are as following.

- scan programs this type of program executed at every scanning cycle.

- task programs these program executed when particular task occurs.

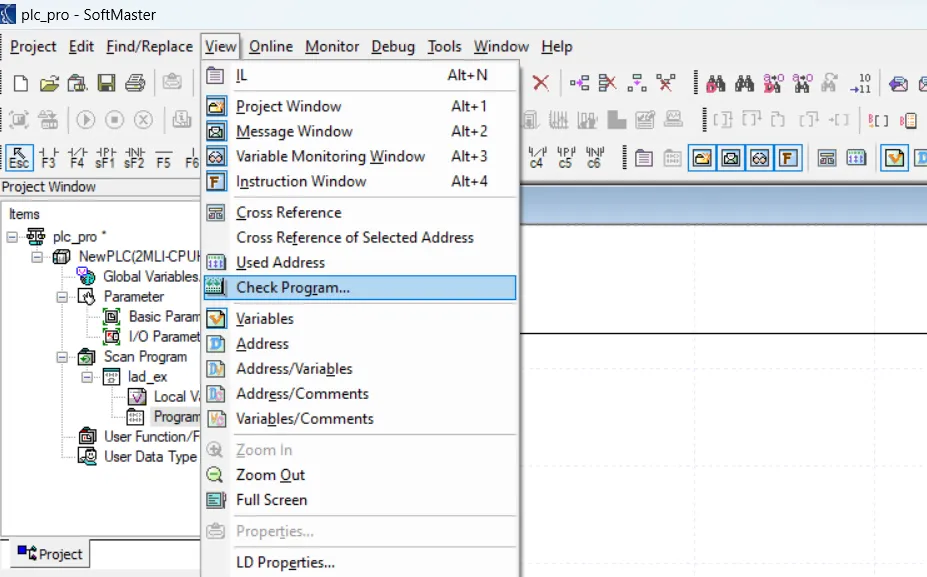

Check PLC Program error and warning

before download check plc program to do this goto view than select check program if any error occurs during program check and resolve the error than again check your program. this will verifies a program while checking the program execution and data.

PLC Simulator in honeywell SoftMaster PLC

Simulator help to test and debug program without physical controller. simulator have some limitation but you can test your program to open simulator goto Tools than select Start Simulator. The SoftMaster-SIM window open.

Communication setting for PLC

in Online open connection setting for configuration, In the Menu bar click Online > Connection Settings. select available driver of your plc than click to connect button to connect plc with softmaster. in online menu all option are enabled after connection of plc.